Building performance Engines takes a special tooling partnership!

Precision Carbide Cutting Tools

WE ARE BUILT FOR HIGH PERFORMANCE

At SFS, we utilize a combination of the worlds greatest materials, employee skill, and machine prowess to provide for some of the most performance demanding industries, including NASCAR and the Air Jet Industry. This means that our engine design is held to a standard that is seen nowhere else in the industry.

CYLINDER PORTING AND ENGINES

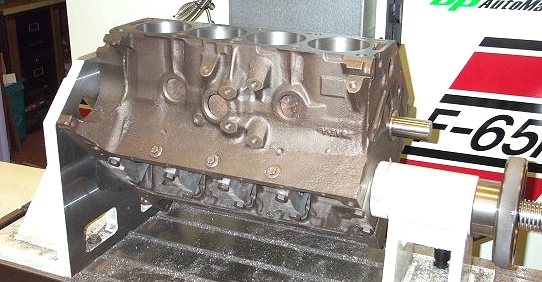

Cylinder porting, fine-tuning the shapes of the ports that direct airflow to and from the cylinders, is one of the most difficult machining jobs. But it is especially important to the engine shops that build the 700-plus horsepower engines for NASCAR and other professional racing teams. Horsepower, torque and acceleration are the keys to winning a race; refining the art of porting can give a team the edge they need to win. It all begins with choosing the right machining tools to blue-print the engine block cylinders, heads and manifold to exacting standards.

When it comes to superior cylinder porting, the majority of high performance engine shops in the world have several things in common: Surfcam CAD/CAM software by Surfware, Inc., Westlake Village, CA…. and precision cutting, boring, and milling tools are all furnished by SFS Carbide Tool Company.

HOW WE DO IT

The process of porting is more of an art than a science. An initial Port and engine block CNC cutting tools prototype is created by hand, tested for optimum airflow and power, then refined by hand machining until the desired performance is achieved. For a prototype cylinder head one exhaust port, one intake port and one chamber are developed. Once the design is complete, the part is digitized, and computerized surfaces are generated. To create all the ports required for a cylinder head, the port surfaces are duplicated and positioned in the correct locations. Then the CNC toolpath is generated to cut the part. CAM/CNC machining the ports in this manner is faster and produces a better-quality product. Ports can be cut in less than one tenth the time it takes to cut them by hand and the ports are consistently the same. Once a design is complete any number of heads or manifolds can be produced that are exactly alike, if your machining tools hold to consistent tolerances. Our tools also can be made to work with any6 brand auto changing tool device in a CNC machining center

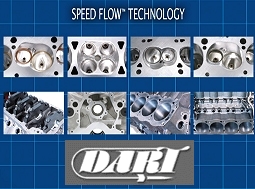

DART'S SPREAD-PORT HEADS

The company has expanded its product line to include aluminum and cast-iron engine blocks that are designed to meet the specialized needs of racers and performance enthusiasts. Dart components are developed in-house, manufactured on Dart’s own CNC machining centers, and tested on Dart’s computer-controlled engine dyno. Maskin keeps current with the continuous advances in racing technology through Dart’s in-house engine program. Dart also supports the sport as an NHRA and IHRA Major Sponsor.

“Our engine program and our daily interaction with leading engine builders and winning racers keeps Dart on the leading edge of technology,” Maskin explains. “We apply everything we learn to produce more powerful and more reliable parts for Dart customers.”Dart Machinery’s Technology Center in Troy, Mich., houses the company’s administrative offices, the R&D headquarters, and inspection, machining and warehouse operations. The immense CNC machining centers that produce Dart heads and blocks from raw castings are located in a separate manufacturing facility in nearby Melvindale.

The Right Tool for the Job Does Make a Difference

SFS Carbide Tool Catalog

11.2MB (high resolution)

SFS Carbide Tool Catalog

1.4MB (low resolution)

- We provide manufacturing to exact specifications.

- Products are inspected multiple times during the production process to ensure consistency and product integrity.

- All products are produced to extend tool life by using only the highest quality materials to enhance their performance at our Michigan plant for all machining applications.

- Automotive CNC Blueprinting of cylinder heads and other High-Performance engine block finishing requires special cutting and polishing tools. The term "blueprinting" describes machining an engine block to exact factory specifications. The block must be bored and all the deck surfaces milled according to the crankshaft centerline. SFS excels in making the tooling for automotive, aviation and motorcycle engine building applications.

- Our 90 years of experience, as a precision metalworking toolmaker and manufacturer, is matched only by our willingness to take on tooling jobs ignored by our competition.

EMAIL OUR STAFF

Business Hours: Monday – Friday: 6:00 am – 3:30 pm EST